At Leadshine, we understand the challenges of designing efficient motion systems. Traditional stepper motor setups often require separate drivers, extensive wiring, and careful component matching. This can increase both installation time and overall system cost. As a trusted stepper motor manufacturer, we provide solutions that address these challenges. Our integrated stepper motor products combine high-performance drives and motors into a single compact unit, streamlining system design and reducing complexity.

Advantages of Integrated Stepper Motors

Integrated stepper motors offer several benefits for industrial automation, CNC machinery, and other applications requiring precise motion control. By combining the motor and driver into one unit, wiring complexity is significantly reduced, and fewer components are needed. This integration not only saves installation time but also reduces the risk of wiring errors, improving system reliability.

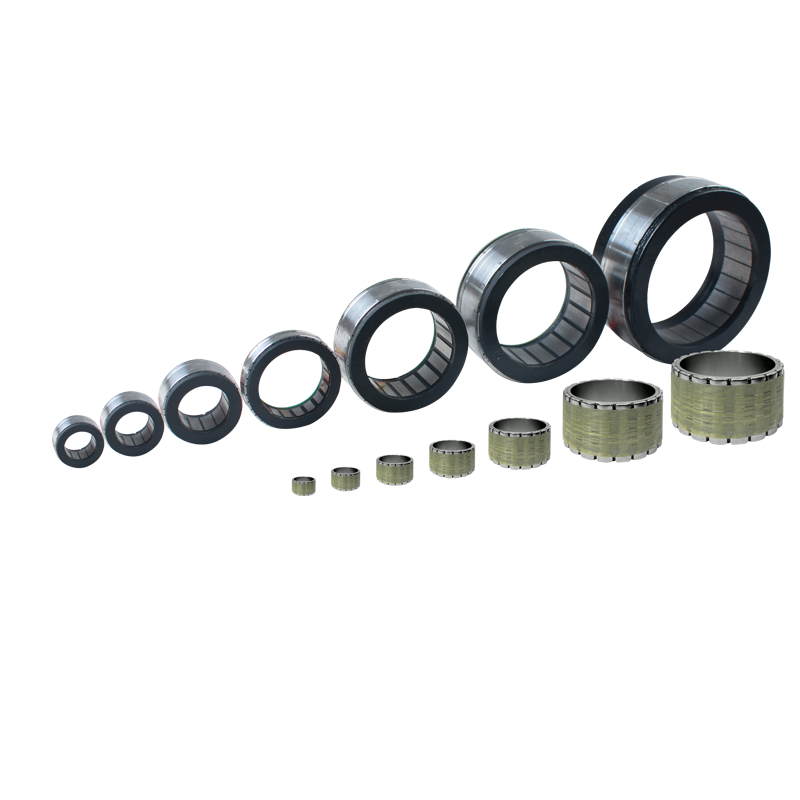

Our integrated stepper motors are available in popular frame sizes such as NEMA 17, NEMA 23, and NEMA 24. These sizes are compatible with a wide range of applications, from compact desktop machines to mid-sized industrial equipment. Each motor features a high-performance digital stepper drive built directly into the motor housing, ensuring smooth motion, precise positioning, and efficient operation.

Cost-effective Solutions for Motion Systems

Choosing an integrated stepper motor from Leadshine provides a cost-effective package for simple motion systems. The combined design minimizes the number of components, reducing material and assembly costs. The compact footprint saves valuable space in machine enclosures, allowing more flexibility in system layout. Additionally, the ease of installation reduces labor requirements and shortens setup time, resulting in a more efficient deployment process.

Leadshine's integrated stepper motors are engineered for reliability. Each motor undergoes rigorous testing to ensure consistent performance and long-term durability. The digital drives incorporated in our motors offer advanced features, such as microstepping, current control, and torque optimization, helping systems maintain accuracy even under varying load conditions.

Applications Across Industries

Integrated stepper motors from Leadshine are suitable for a variety of applications. They are commonly used in CNC machinery, 3D printers, packaging equipment, lab automation, and other industrial systems requiring precise motion. The reduced wiring and simplified installation make them ideal for both new designs and retrofitting existing machines. By selecting a compact, self-contained motion solution, manufacturers can streamline assembly and improve overall system efficiency.

Conclusion

As a dedicated stepper motor manufacturer, Leadshine focuses on providing high-quality, reliable, and efficient motion solutions. Our integrated stepper motor products combine motor and driver in a single compact unit, reducing wiring complexity, saving installation time, and lowering system costs. Available in NEMA 17, 23, and 24 frame sizes, these integrated motors offer precise control, smooth operation, and a cost-effective solution for a wide range of industrial applications. Choosing Leadshine means simplifying motion system design while maintaining performance and reliability.